Die Creation and Order Repetition

For the first order of a customized award, the tool – a stamping die or a mould, depending on the chosen material – needs to be created:

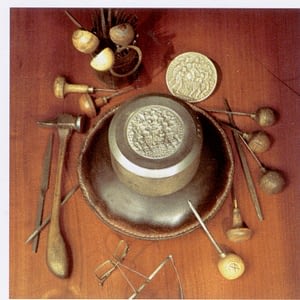

- For stamped medals or insignias , it consists of a piece of steel that shows the medal in negative relief: it is quenched so that it will resist the multiple strokes inherent to the manufacturing process. The creation of a stamping die is a core know-how of our organization, engraving steel being quite a complex task.

Stamping die for a medal - For bronze casting awards , a resin model is made and then used in the sand moulding process.

A 3D resin model for a bronze casting award

On the first order, the client is charged the tools creation sharing cost : it can represent more than 50% of total cost for a 30-medal order.

The tooling cost depends on the characteristics of the customized award:

- It is closely related to the size of the medal – the diameter or the largest dimension between height and width of the medal.

e.g., the die cost of a 73mm (2.9″) round medal is twice as much as that of a 50mm (2″) round medal. - It depends highly on the type of relief chosen for the award: sculptured (3D) relief dies are almost twice as costly as simple relief (2D) dies for medals of the same size.

- If you choose to have a back side on your medal, the back die creation sharing cost is added to the face die creation sharing cost.

Once it has been created, the die will be kept in our workshop for potential new orders made within the 3-years following your last order.

Within this period, the die creation sharing cost will be waivered on new orders.